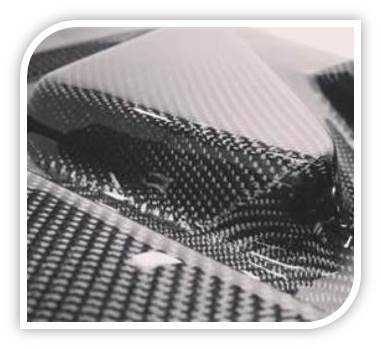

Enhancing the Aesthetics and Durability of Carbon Fiber and Other Composites with Coatings

Coating is an essential step in the manufacturing process of composites to ensure that the parts produced are protected against environmental elements and to achieve the desired visual finish. Coating can also enhance the durability and performance of composites.

For carbon fiber parts, we offer both gloss and matte finish clear coating. The clear coat not only gives a desirable appearance but also protects the carbon fiber from UV light, scratches, and abrasions. The gloss finish provides a shiny and smooth surface, while the matte finish offers a non-reflective surface with a slight texture.

In addition to carbon fiber, we also provide coating for other composites such as glass fiber parts. Glass fiber parts require coating for similar reasons as carbon fiber parts, such as UV protection and abrasion resistance.

The coating material used depends on the specific application and requirements. For example, if the part is exposed to high temperatures, a high-temperature resistant coating is necessary. Similarly, if the part is exposed to harsh chemicals, a chemical resistant coating is required.

There are several advantages to using coatings on composites. Coatings can enhance the appearance of the parts, making them more attractive and professional-looking. Additionally, coatings can improve the durability and resistance of composites, extending their lifespan and reducing maintenance costs.

However, there are also some disadvantages to consider. Coatings can add weight to the parts, which may be an issue in certain applications. Additionally, the application process of coatings can be time-consuming and costly, especially for large and complex parts.

Overall, coatings are an important aspect of the manufacturing process for composites. They provide protection, enhance appearance, and improve durability and performance. The specific type of coating used should be chosen based on the application and requirements of the parts.