3D Printing: The Power of Innovation in Composite Production

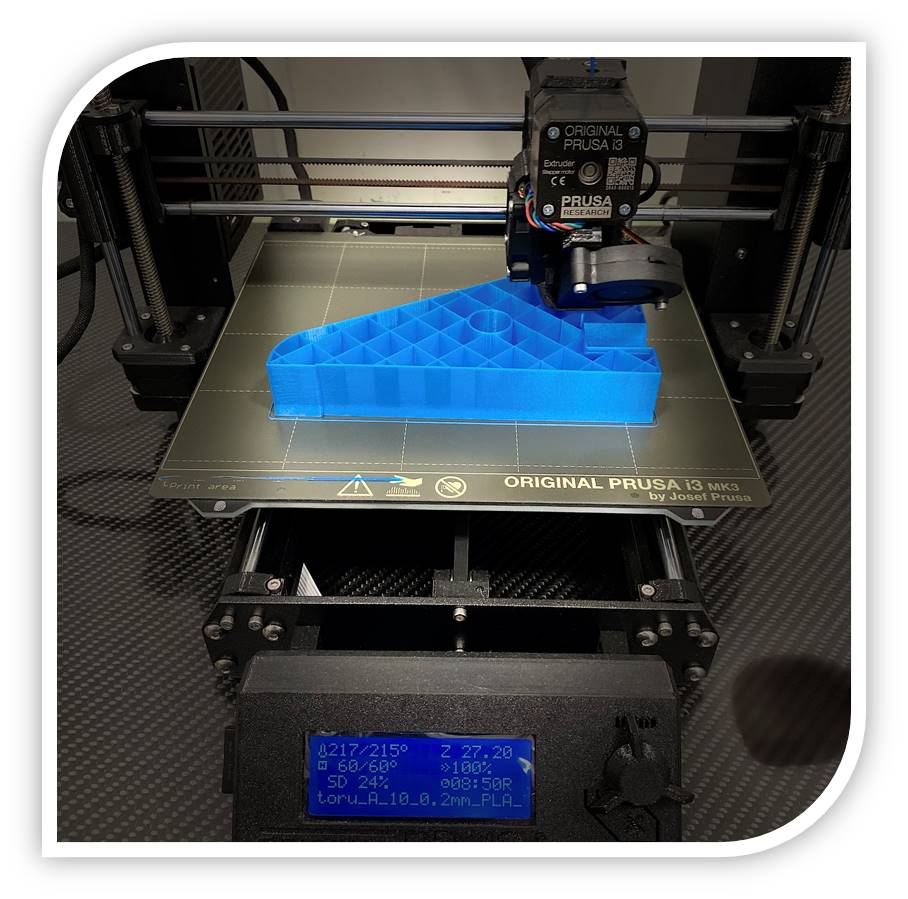

At kopp-voracek spol. s r.o., we pride ourselves on our commitment to cutting-edge technology and innovation in the field of composite production. One of the key tools in our arsenal is our 3D printer, which has proven to be a valuable asset in our manufacturing process.

By using materials such as PLA and PETG, we are able to produce precise and detailed patterns for our mold-making process, as well as jigs and fixtures for drilling holes in our composite products.

But the applications of 3D printing in composite production don't stop there. We also use our printer to create bonding fixtures for joining multiple composite parts together, streamlining our production process and ensuring maximum accuracy and efficiency.

With 3D printing, we have the power to produce complex parts with intricate geometries, something that would be impossible or prohibitively expensive with traditional manufacturing methods. Additionally, our small-scale 3D printing process is cost-effective, allowing us to provide high-quality composite products at competitive prices.

At kopp-voracek, we are committed to pushing the boundaries of composite production and using the latest technology to provide our customers with the best possible products. Contact us today to learn more about our 3D printing capabilities and our full range of composite production services.